Description

CONTACT CUSTOMER SERVICE FOR PRICE AND LEAD TIME.

!!! INSURE THE APPLICATION TESTS FOR THE CORRECT VOLTAGE, CYCLE, AND PHASE BEFORE PURCHASING !!!

260MH Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

260-MH Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

260 MH Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

MH260 Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

MH 260 Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

MH-260 Industrial Material Handler Radial Blade Belt Driven Single Width, Single Inlet

REPLACEMENT MOTOR SINGLE PHASE 115 VOLT: Please email or call for pricing

REPLACEMENT MOTOR THREE PHASE: Please email or call for pricing

REPLACEMENT BEARINGS: Please email of call for pricing

REPLACEMENT SHAFT: Please call or email for pricing

REPLACEMENT BLADE: Please email or call for pricing

REPLACEMENT TOPCAP/LID: Please email or call for pricing

CONTACT CUSTOMER SERVICE FOR PRICE AND LEAD TIME.

MH

Industrial Material Handler

Radial Blade Belt Driven

Single Width, Single Inlet

- The MH wheel is used for light material conveying applications when the airstreams contain small granular material, heavy or tacky dust, or small abrasive particulate matter. It is available in standard and heavy duty designs.

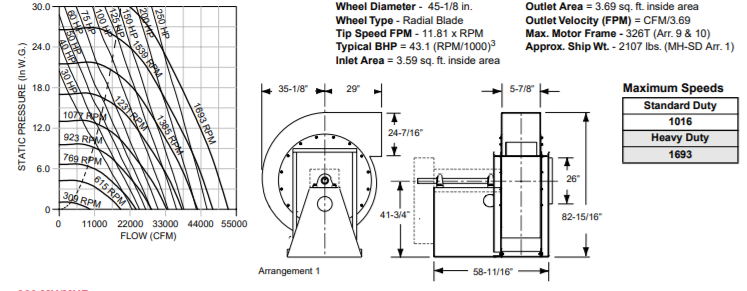

Description: Fan shall be a single width, single inlet radial blade, belt driven industrial material handler.

Certifications: Fan shall be manufactured at an ISO 9001 certified facility. Fan shall be Underwriters Laboratories Classified (as to electrical shock and mechanical hazards only) and CSA Certified (Standard 113-M1984). Fan shall bear the AMCA certified ratings seal for air performance.

Construction: The fan shall be of bolted and welded construction utilizing corrosion resistant fasteners. The scroll wrapper and scroll side panels shall be a minimum 10 gauge steel. The entire fan housing shall have continuously welded seams for leakproof operation and shall be field rotatable to any one of eight discharge positions. Housing side panels shall be rigidly reinforced using structural steel to prevent flexing and vibration at high pressures. Bearing support shall be minimum 1/4″ welded steel. Lifting lugs shall be provided for ease of installation. Unit shall bear an engraved aluminum nameplate and shall be shipped in ISTA certified transit tested packaging.

Coating: All steel fan components shall be Lorenized™ with an electrostatically applied, baked polyester powder coating. Each component shall be subject to a five stage environmentally friendly wash system, followed by a minimum 2 mil thick baked powder finish. Paint must exceed 1,000 hour salt spray under ASTM B117 test method.