Description

CONTACT CUSTOMER SERVICE FOR PRICE AND LEAD TIME.

!!! INSURE THE APPLICATION TESTS FOR THE CORRECT VOLTAGE, CYCLE, AND PHASE BEFORE PURCHASING !!!

70SRSH-B Tamper Proof Downblast Centrifugal Exhaust Ventilator Roof Mounted/ Belt Drive

70-SRSH-B Tamper Proof Downblast Centrifugal Exhaust Ventilator Roof Mounted/ Belt Drive

70.SRSH-B Tamper Proof Downblast Centrifugal Exhaust Ventilator Roof Mounted/ Belt Drive

SRSH-B 70 Tamper Proof Downblast Centrifugal Exhaust Ventilator Roof Mounted/ Belt Drive

SRSH-B-70 Tamper Proof Downblast Centrifugal Exhaust Ventilator Roof Mounted/ Belt Drive

REPLACEMENT MOTOR SINGLE PHASE 115 VOLT: Please email or call for pricing

REPLACEMENT MOTOR THREE PHASE: Please email or call for pricing

REPLACEMENT BEARINGS: Please email of call for pricing

REPLACEMENT SHAFT: Please call or email for pricing

REPLACEMENT BLADE: Please email or call for pricing

REPLACEMENT TOPCAP/LID: Please email or call for pricing

CONTACT CUSTOMER SERVICE FOR PRICE AND LEAD TIME.

SRSH-B

Tamper Proof

Downblast Centrifugal

Exhaust Ventilator Roof

Mounted/ Belt Drive

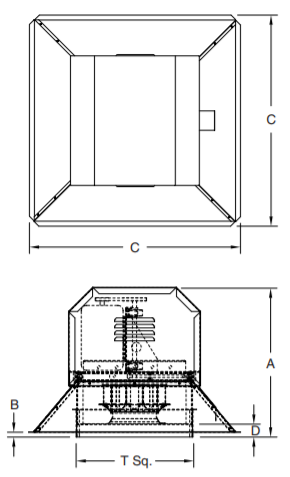

Description: Fan shall be a galvanized steel, tamper proof, roof mounted, belt driven, downblast centrifugal exhaust ventilator.

Certifications: Fan shall be manufactured at an ISO 9001 certified facility. Fan shall be listed by Underwriters Laboratories (UL 705) and UL listed for Canada (cUL 705). Fan shall bear the AMCA Certified Ratings Seal for Air Performance.

Construction: The fan shall be of bolted, riveted and welded construction utilizing corrosion resistant fasteners. The discharge skirt shall be 16 gauge galvanized steel construction fastened with stainless steel rivets. An 18 gauge galvanized steel hood shall have a stainless steel .25” diameter full length hinge to provide secure access into the motor compartment. The hood shall have two .125” gauge x 1.25” wide restraining bars to hold the hood in the open locked position when servicing. A heavy-duty .125” thick stainless steel locking hasp shall provide complete security with the use of a standard padlock concealed under the skirt. An integral conduit chase shall be provided through the curb cap and into the motor compartment to facilitate wiring connections. The motor, bearings and drives shall be mounted on a 14 gauge steel power assembly, isolated from the unit structure with rubber vibration isolators. The complete power assembly, motor and wheel assembly can be removed for servicing without disassembling the hood or skirt assemblies. Lifting lugs shall be provided to help prevent damage from improper lifting. Unit shall bear an engraved aluminum nameplate and shall be shipped in ISTA Certified Transit Tested Packaging.